In our daily life, plastic products can be seen everywhere. Many people will feel that plastic products are not as easy to mold as leather products, textiles, wood products, etc., But the truth is that plastic products is easy get mold during transportation.

1, plastic products in the production of some additives used is one of the causes of plastic mold

The main component of plastic raw materials resin has a macromolecular hydrocarbon long chain structure, which is not easy to breed and multiply mold, but in the production of plastic products, a variety of small molecule additives are generally added, such as fatty acid plasticizer, egg fat dispersant, grease, antioxidant, etc., which provides nutrients for microbial growth, making mold easy to parasitize and multiply.

2.Plastic products in the storage and transportation environment for a long time in a high humidity environment, will be more prone to mold. Water is an important growth factor for mold growth. While it’s true that plastic products are less prone to mold than high-risk materials like leather,

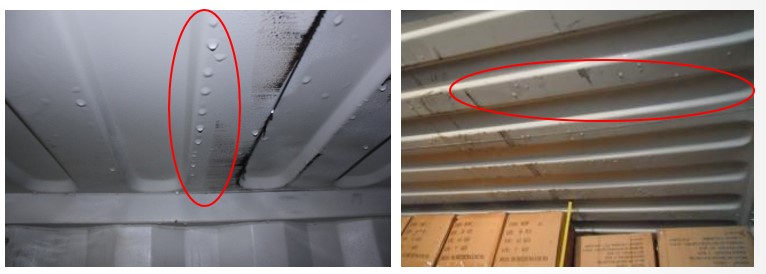

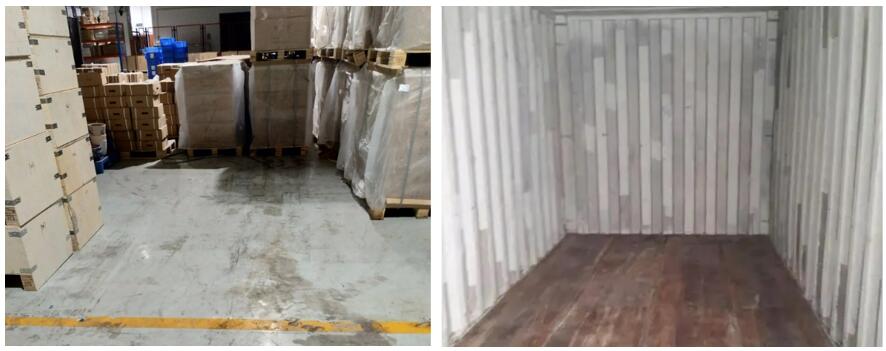

然而, if you do not pay attention to temperature and humidity control in the storage and transportation process, plastic products will also face the risk of mold, especially in the container transportation link, container rain, cargo sweat may cause plastic products to mold.

Plastic products in the production, storage, transportation process cleanliness is not up to standard may also cause plastic products mold.The cleanliness of the overall environment is also important during production and storage, as dirt and dust in the air can be deposited on the plastic and provide additional soil for mold spores.

3.Go mouldy will reduce the transparency of plastic products, change color, become brittle, and damage the performance of plastic products, resulting in shortened service life. The precision and sensitivity of plastic instruments are reduced, which will seriously affect the reliability of plastic products or systems containing plastic parts.

4.For plastic products mildew, there are many manufacturers will choose to add desiccant in the production process of plastic products, but antibacterial and mildew materials in the export abroad, must follow the local access regulations, so before use must be a certain understanding of the composition of desiccant. At the same time, we remind you to pay attention to the environment during production, storage and transportation to avoid the growth of mold at the source. We recommend you to use CARGODRY desiccant in product packaging and containers, which can keep the environment of your goods at a low humidity level during storage and transportation, thus helping you reduce the risk of moisture and mold of your products.

4.For plastic products mildew, there are many manufacturers will choose to add desiccant in the production process of plastic products, but antibacterial and mildew materials in the export abroad, must follow the local access regulations, so before use must be a certain understanding of the composition of desiccant. At the same time, we remind you to pay attention to the environment during production, storage and transportation to avoid the growth of mold at the source. We recommend you to use CARGODRY desiccant in product packaging and containers, which can keep the environment of your goods at a low humidity level during storage and transportation, thus helping you reduce the risk of moisture and mold of your products.